Clear records

history record

cancel

Clear records

history record

Why do medical device blister packaging use fixed blister packaging?

With the continuous advancement of China's medical technology, while medical devices are constantly being updated and changed, many packaging manufacturers are paying more and more attention to research and investment in medical packaging and sterilization. As a result, medical device blister packaging is also constantly changing. Innovation and progress, do you know why fixed blister packaging is used for medical device blister packaging?

The following is a brief analysis of the forms of several medical device blister packaging.

one,

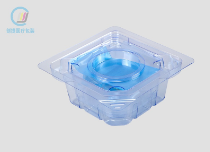

This double-layer medical device blister packaging adopts layered packaging. It is packaged with medical-grade TPU material and matched with a blister box. The outer layer is heat-sealed with DuPont paper to form a sterile barrier system. This packaging method can It secures medical device products inside well and plays a very protective role.

two,

Compared with the one above, this medical device blister packaging has a simpler structure inside the box. In contrast, the packaged medical devices are more flexible. However, this kind of device cannot fix medical devices well inside and can only load medical devices with low requirements.

In contrast, fixed blister packaging for medical device blister packaging is more suitable for those with high packaging requirements, because the function of fixed blister is to fix the product in a grooved blister box to prevent the packaged product from shaking and reduce vibration. , to protect the product from friction and scratches.

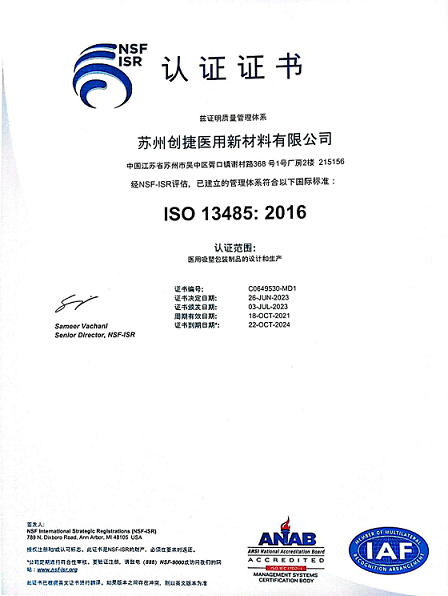

Suzhou Chuangjie Medical New Materials Co., Ltd. has advanced production equipment and testing equipment, as well as a complete after-sales service system, which provides a solid quality foundation for Suzhou Chuangjie Medical New Materials Co., Ltd. and dedicates products and innovative services to new and old customers. , share value and achievements with partners. Implements ISO13485:2016 and ISO9001 quality management systems, and is also a member of the Medical Device Association. We have a product quality inspection center. During the product production process, we implement operating procedures such as incoming material inspection, process inspection, and finished product factory inspection. From raw materials entering the factory to finished products leaving the factory, strict control is carried out to ensure product quality.

The browser own share function is also very useful~

The browser own share function is also very useful~