Clear records

history record

cancel

Clear records

history record

June 1-3, 2023 | See you at Suzhou Medtec China~

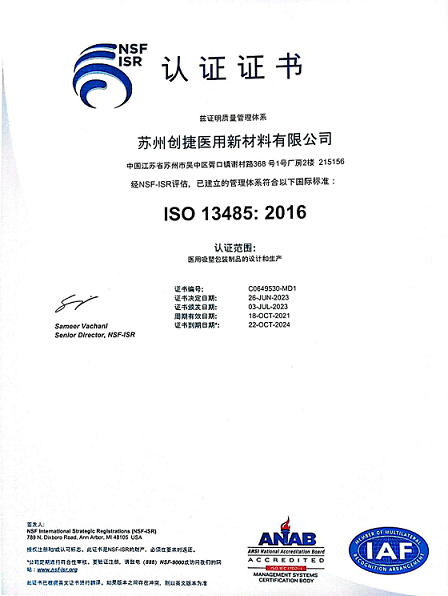

Suzhou Chuangjie Medical New Materials Co., Ltd. was established in May 2013, focusing on the R&D, production and manufacturing of medical blister packaging, medical device blister trays, TPU material medical packaging, medical accessories injection molding and other products. The company has passed IS013485:2016 and IS09001:2015 quality management system certification, and has CLASS 70,000 clean workshop and pure water system. Advanced thermoforming equipment, efficient automated production lines, advanced production technology, strong production capacity, and experienced design and R&D teams enable us to provide overall packaging solutions quickly and accurately. The company provides customized packaging design solutions and personalized services. With continuous technological innovation, high-quality products, and efficient business collaboration capabilities, it has reached long-term strategic partnerships with a number of large medical device manufacturers to achieve collaboration with customers. Win-win!

PETG medical blister packaging

It uses medical-grade raw materials PETG and high-precision aluminum film, and is produced in a Class 10,000 clean workshop; the packaging method heat-sealed with Tyvek cover material has bacterial barrier properties and good sealing performance. It can achieve aseptic operation and clean peeling, and meet the relevant legal and regulatory requirements for medical device packaging materials.

TPU medical packaging

TPU medical packaging is characterized by wear resistance, puncture resistance, aging resistance, etc. It can effectively block the contamination of medical devices by falling particles generated by friction in the inner packaging. The puncture resistance and wear resistance improve the safety and reliability of the transportation process of medical devices. .

APET medical blister packaging

APET material features are cheap, high strength (lower than PETG); impact resistance; aging for 2 to 3 years; cannot be sterilized by radiation, and is suitable for EO sterilization. It is commonly used in Class I and II medical devices and can be sealed with Tyvek cover materials.

June 1-3, 2023 | See you at Suzhou Medtec China~

The browser own share function is also very useful~

The browser own share function is also very useful~