Clear records

history record

cancel

Clear records

history record

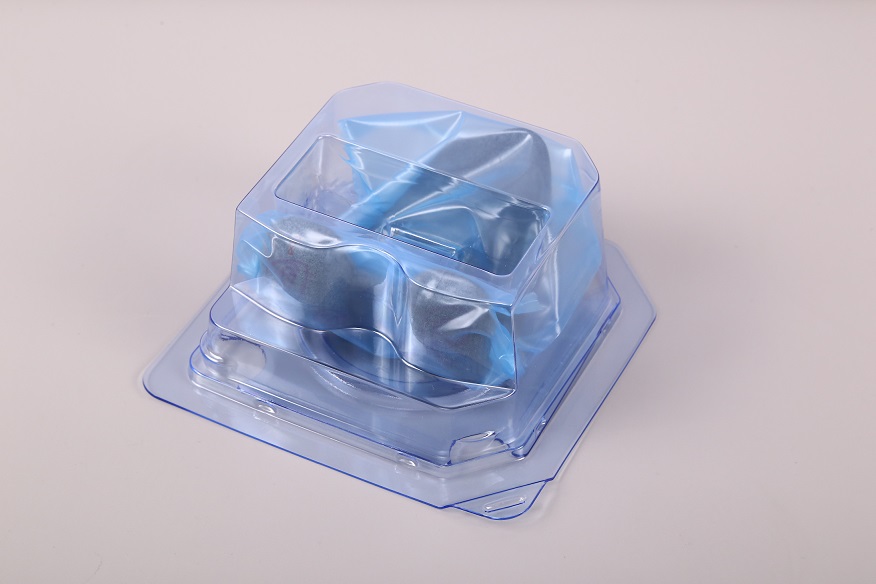

Artificial joint double-layer sterile blister box

The double-layer sterile blister box for artificial joints is produced in a Class 10,000 clean workshop using medical-grade raw materials PETG and high-precision aluminum film. It adopts a double-layer hard blister box and a heat-sealed packaging method of Tyvek cover material, which has bacterial barrier properties. It has good resistance and sealing performance, strong protection for implantable devices, and is suitable for sterilization methods such as EO, irradiation, and low temperature.

For general products, packaging is just to include the product, protect the product and be beautiful; but for medical blister boxes, it also needs to consider the following points:

1. It is necessary to provide protection, identification, proprietary performance, ease of use and special applications for the use and display of the device;

2. It is necessary to understand the purpose, size, shape of the product and its unique characteristics (such as sharp edges, points, brittleness, etc.), distribution environment, application (convenient for clean opening by medical staff) and barrier requirements. For choosing appropriate materials and It is very important to successfully design the final packaging.

The protective performance of medical blister boxes is wider, and its advantages are reflected in the following points:

1. Sterility: The device can be terminally sterilized by one or more methods without the material being degraded within the specified time;

2. Shelf life: Ensure the so-called barrier stability of the material throughout the product’s life cycle;

3. Environmental aspects: Isolate moisture, air, bacteria, and oxygen;

4. Physical aspect: Able to provide dynamic protection, resist impact and wear, and provide structural support. These characteristics will be fully considered in the early design of medical blister boxes

In addition, we use medical-grade TPU packaging developed and designed by our company for the inner packaging of some implantable devices, and use a hard blister box for the outer layer to enhance the protective performance of the product.

Artificial joint double-layer sterile blister box

The double-layer sterile blister box for artificial joints is produced in a Class 10,000 clean workshop using medical-grade raw materials PETG and high-precision aluminum film. It adopts a double-layer hard blister box and a heat-sealed packaging method of Tyvek cover material, which has bacterial barrier properties. It has good resistance and sealing performance, strong protection for implantable devices, and is suitable for sterilization methods such as EO, irradiation, and low temperature.

For general products, packaging is just to include the product, protect the product and be beautiful; but for medical blister boxes, it also needs to consider the following points:

1. It is necessary to provide protection, identification, proprietary performance, ease of use and special applications for the use and display of the device;

2. It is necessary to understand the purpose, size, shape of the product and its unique characteristics (such as sharp edges, points, brittleness, etc.), distribution environment, application (convenient for clean opening by medical staff) and barrier requirements. For choosing appropriate materials and It is very important to successfully design the final packaging.

The protective performance of medical blister boxes is wider, and its advantages are reflected in the following points:

1. Sterility: The device can be terminally sterilized by one or more methods without the material being degraded within the specified time;

2. Shelf life: Ensure the so-called barrier stability of the material throughout the product’s life cycle;

3. Environmental aspects: Isolate moisture, air, bacteria, and oxygen;

4. Physical aspect: Able to provide dynamic protection, resist impact and wear, and provide structural support. These characteristics will be fully considered in the early design of medical blister boxes

In addition, we use medical-grade TPU packaging developed and designed by our company for the inner packaging of some implantable devices, and use a hard blister box for the outer layer to enhance the protective performance of the product.

The browser own share function is also very useful~

The browser own share function is also very useful~