Clear records

history record

cancel

Clear records

history record

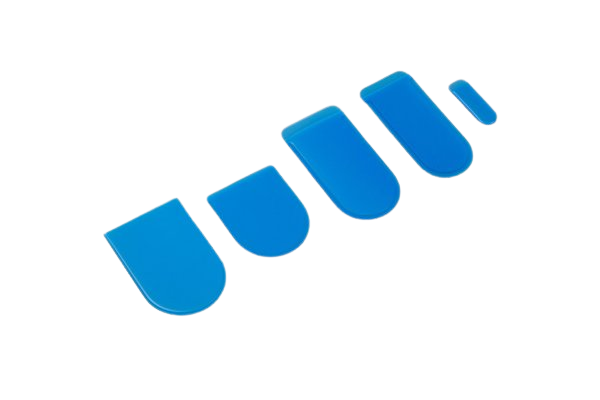

TPU protective cap

During the packaging process, medical devices will directly come into contact with the original packaging. When the surface of the device itself is rough or has a special coating, the requirements for the original packaging are extremely strict. Using medical-grade TPU packaging can reduce packaging costs, effectively prevent the surface of the device from being worn, and strengthen the impact of packaging on product safety.

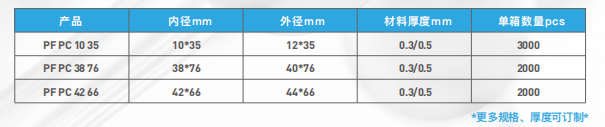

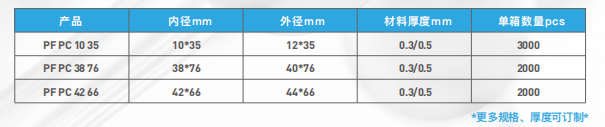

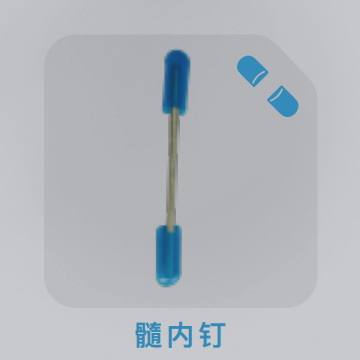

TPU protective caps are mostly used to protect sharp-edged medical instruments, such as screws, Kirschner wires, puncture needles, etc. It is an ideal replacement for risky medical packaging materials such as silicone, PVC, and sponge. Dimensions are as follows:

With advanced medical-grade raw materials, packaging design expertise and clean workshop processing capabilities, we are able to design and develop packaging solutions that meet customer needs.

TPU protective cap

During the packaging process, medical devices will directly come into contact with the original packaging. When the surface of the device itself is rough or has a special coating, the requirements for the original packaging are extremely strict. Using medical-grade TPU packaging can reduce packaging costs, effectively prevent the surface of the device from being worn, and strengthen the impact of packaging on product safety.

TPU protective caps are mostly used to protect sharp-edged medical instruments, such as screws, Kirschner wires, puncture needles, etc. It is an ideal replacement for risky medical packaging materials such as silicone, PVC, and sponge. Dimensions are as follows:

With advanced medical-grade raw materials, packaging design expertise and clean workshop processing capabilities, we are able to design and develop packaging solutions that meet customer needs.

The browser own share function is also very useful~

The browser own share function is also very useful~