Clear records

history record

cancel

Clear records

history record

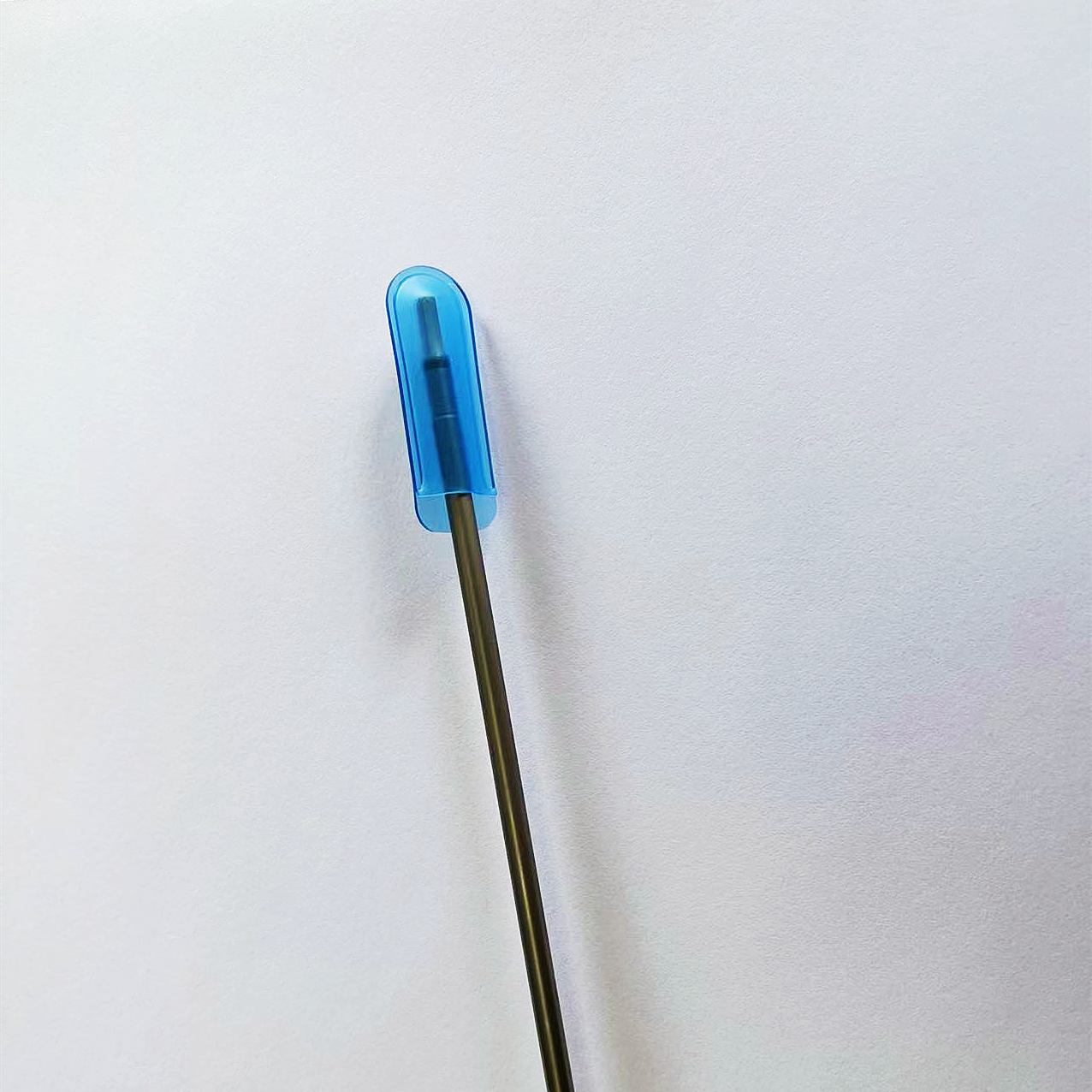

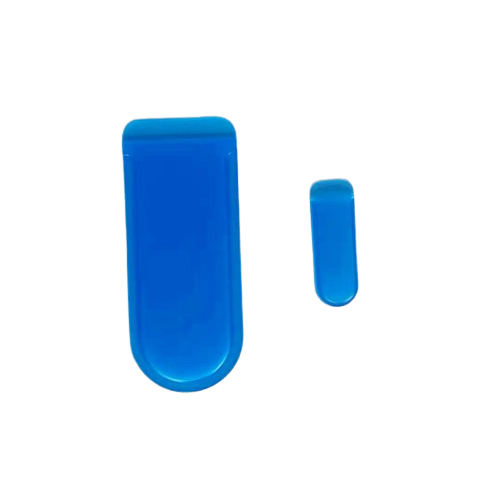

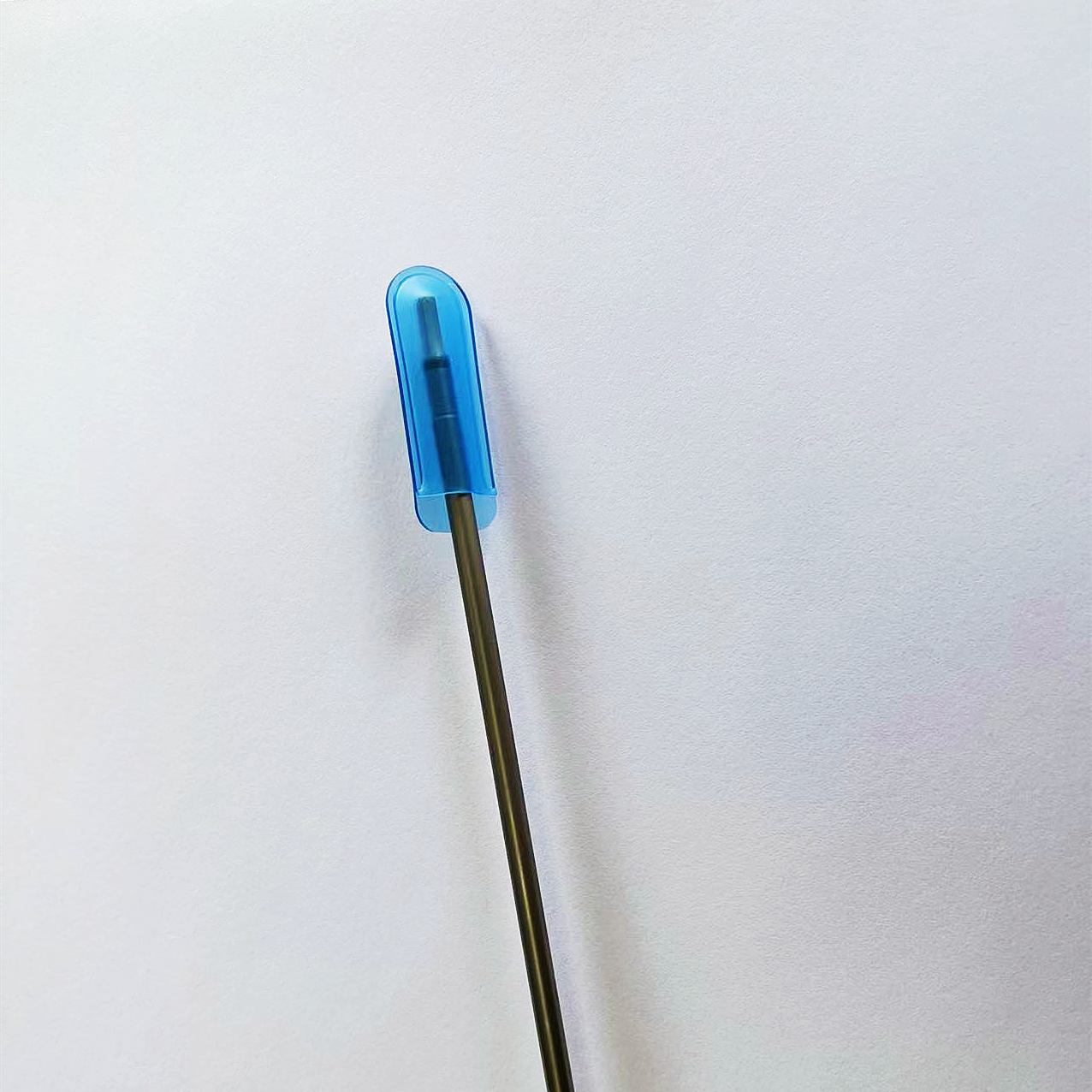

Protective cap 10*35/32*76-sharp instruments

We have newly developed a medical grade TPU material packaging - protective cap 10*35/32*76, which is mainly used to protect medical devices with sharp edges. Such as screws, Kirschner wires, puncture needles, etc. It is an ideal replacement for risky medical packaging materials such as silicone, PVC, and sponge.

Dimensions are as follows:

| product | Inner diameter mm | Outer diameter mm | Material thickness mm | Packing quantity |

| PF PC 10 34 | 10*35 | 12*35 | 0.3/0.5 | 100/5000 |

| PF PC 26 73 | 26*73 | 32*76 | 0.3/0.5 | 100/5000 |

Medical-grade TPU material packaging is mainly used for orthopedic device packaging. It is a soft material that is puncture-resistant and friction-resistant. It is more effective when used with rigid blister boxes or paper plastic bags to form a sterile barrier system.

When used in the packaging of some puncture needles, the 10*35 protective cap can effectively block the contamination of medical devices by falling particles caused by friction in the inner packaging, ensuring the sterility and integrity of implantable medical devices before use. Compared with traditional packaging solutions, its puncture resistance and wear resistance improve the safety and reliability of the transportation process of medical devices, such as orthopedic screws, surgical instruments, etc.

Protective cap 10*35/32*76-sharp instruments

We have newly developed a medical grade TPU material packaging - protective cap 10*35/32*76, which is mainly used to protect medical devices with sharp edges. Such as screws, Kirschner wires, puncture needles, etc. It is an ideal replacement for risky medical packaging materials such as silicone, PVC, and sponge.

Dimensions are as follows:

| product | Inner diameter mm | Outer diameter mm | Material thickness mm | Packing quantity |

| PF PC 10 34 | 10*35 | 12*35 | 0.3/0.5 | 100/5000 |

| PF PC 26 73 | 26*73 | 32*76 | 0.3/0.5 | 100/5000 |

Medical-grade TPU material packaging is mainly used for orthopedic device packaging. It is a soft material that is puncture-resistant and friction-resistant. It is more effective when used with rigid blister boxes or paper plastic bags to form a sterile barrier system.

When used in the packaging of some puncture needles, the 10*35 protective cap can effectively block the contamination of medical devices by falling particles caused by friction in the inner packaging, ensuring the sterility and integrity of implantable medical devices before use. Compared with traditional packaging solutions, its puncture resistance and wear resistance improve the safety and reliability of the transportation process of medical devices, such as orthopedic screws, surgical instruments, etc.

The browser own share function is also very useful~

The browser own share function is also very useful~