Clear records

history record

cancel

Clear records

history record

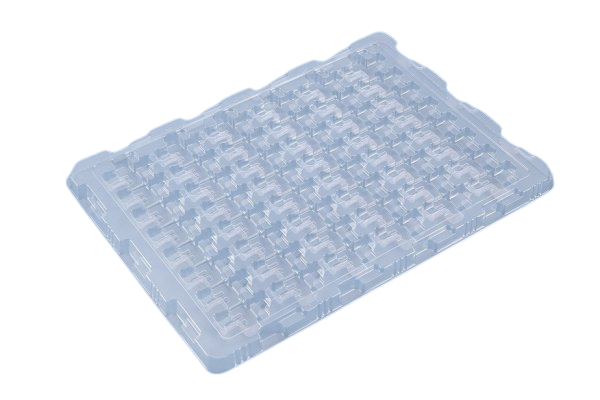

Anti-static blister tray

Anti-static blister trays, also known as anti-static blister trays, are made by adding a certain conductive medium to ordinary blister raw material sheets, so that the packaged products have a certain degree of conductivity and do not generate static electricity. According to the amount of conductive medium added and the actual measured surface resistance value of the product, we generally call blister products with surface resistance values between 10 to the 11th power of 10 ohms as anti-static blister products.

The main purpose is to eliminate static electricity, which can effectively release the static charge accumulated on the surface of the object, so that charge accumulation and high potential difference will not occur; it can greatly reduce the damage rate of electronic products during the production and transportation process, and is widely used in the production of electronic component products. Process turnaround loading, packaging, storage and transportation. Suitable for various auto parts and electronic component products.

Anti-static blister trays are made of PS, PET and other materials and are divided into three levels: Conductive: surface resistance value is 103~105Ω Semi-conductive: surface resistance value is 106~108Ω Anti-static: surface resistance value is 109~1011Ω

If you want anti-static blister trays, you can choose Suzhou Chuangjie Medical New Materials Co., Ltd.

Anti-static blister tray

Anti-static blister trays, also known as anti-static blister trays, are made by adding a certain conductive medium to ordinary blister raw material sheets, so that the packaged products have a certain degree of conductivity and do not generate static electricity. According to the amount of conductive medium added and the actual measured surface resistance value of the product, we generally call blister products with surface resistance values between 10 to the 11th power of 10 ohms as anti-static blister products.

The main purpose is to eliminate static electricity, which can effectively release the static charge accumulated on the surface of the object, so that charge accumulation and high potential difference will not occur; it can greatly reduce the damage rate of electronic products during the production and transportation process, and is widely used in the production of electronic component products. Process turnaround loading, packaging, storage and transportation. Suitable for various auto parts and electronic component products.

Anti-static blister trays are made of PS, PET and other materials and are divided into three levels: Conductive: surface resistance value is 103~105Ω Semi-conductive: surface resistance value is 106~108Ω Anti-static: surface resistance value is 109~1011Ω

If you want anti-static blister trays, you can choose Suzhou Chuangjie Medical New Materials Co., Ltd.

The browser own share function is also very useful~

The browser own share function is also very useful~